Industrial Cyclone Dust Collector: Working Principle & Applications

Industrial cyclone dust collectors are an effective solution for controlling dust in factories across Vietnam. Discover how they work, their advantages, and their applications in industries such as food processing, coating, bicycle manufacturing, automotive, and commercial buildings.

Why Is Industrial Dust Control Important?

In factories, industrial dust causes multiple problems:

- Reduces product quality.

- Shortens the lifespan of machines & equipment.

- Poses health risks for workers.

- Leads to violations of environmental regulations.

💡 That’s why industrial dust collection systems are essential. Among these, the Cyclone dust collector is widely used due to its simple design and high efficiency.

What Is a Cyclone Dust Collector?

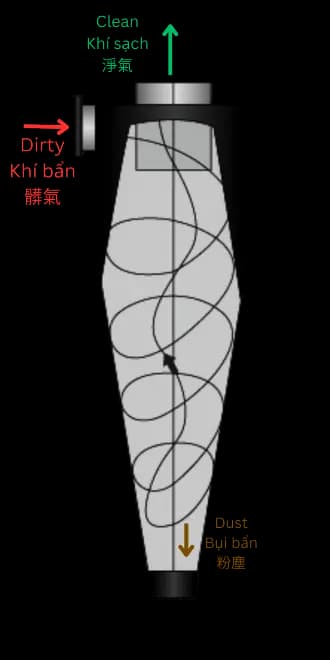

A Cyclone dust collector uses centrifugal force to separate dust particles from the airstream.

👉 Principle: Dust-laden air spins inside the conical chamber, heavy particles are forced outward and fall into the hopper, while clean air rises and exits.

⚙️ Best suited for: coarse dust, dry dust, or high-concentration dust environments.

📷

How Does a Cyclone Dust Collector Work?

| Step | Description |

|---|---|

| 1 | Dusty air enters the cyclone tangentially |

| 2 | Spiral airflow creates centrifugal force |

| 3 | Dust particles are thrown to the wall and fall down |

| 4 | Clean air exits through the central outlet |

Dry Cyclone vs. Wet Cyclone

- Dry Cyclone: suitable for coarse, non-sticky dust.

- Wet Cyclone: uses water spray to capture fine and sticky dust, also helps odor control.

👉 Learn more: Wet Filtration Systems

👉 Learn more: Dry Filtration Systems

Common Types of Cyclone Dust Collectors

1. Single Cyclone

Simple design, cost-effective, ideal for small airflow volumes.

2. Multi-Cyclone

Multiple small cyclones combined for higher efficiency.

3. Wet Cyclone

Integrated water spray system for handling sticky dust and odors.

👉 Explore related products:

Applications in Vietnam

Cyclone dust collectors are widely applied in:

- 🥖 Food Processing: flour, grain, sugar dust removal.

- 🎨 Coating & Painting: powder coating, paint dust control.

- 🚲 Bicycle & Automotive: metal grinding and polishing dust.

- 🏨 Hotels & Commercial Buildings: support for HVAC systems and smoke extraction.

👉 Real-world solutions: Air Pollution Projects & Solutions

Key Advantages

✅ High efficiency for coarse dust removal.

✅ Simple design → minimal maintenance.

✅ Low operating cost (no filter bags).

✅ Can be combined with ESP or Baghouse for fine dust.

✅ Environmentally friendly solution.

When to Use a Cyclone Dust Collector?

- When dust particles are large and heavy.

- When durability and low maintenance are required.

- As a pre-filter to reduce the load on ESPs or baghouses.

👉 Learn more: Electrostatic Precipitator (ESP)

FAQs about Cyclone Dust Collectors

Is a cyclone dust collector effective for fine dust?

→ Not ideal for particles < 10 microns. Best combined with ESP or bag filters.

Does a cyclone dust collector consume much electricity?

→ Very little — only the fan power is required.

What is the lifespan of a cyclone?

→ Stainless steel models can last 10–15 years with proper maintenance.

Conclusion

The industrial cyclone dust collector is a simple, durable, and cost-effective solution for dust control in Vietnam. It is especially effective in industries such as food processing, coating, bicycle, automotive, and hospitality.

Contact Us

Looking for a reliable industrial cyclone dust collector for your factory?

We provide customized design & installation tailored to your industry.

👉 Contact Us Now

📧 Email: info@codanh.com